METALLIC INK

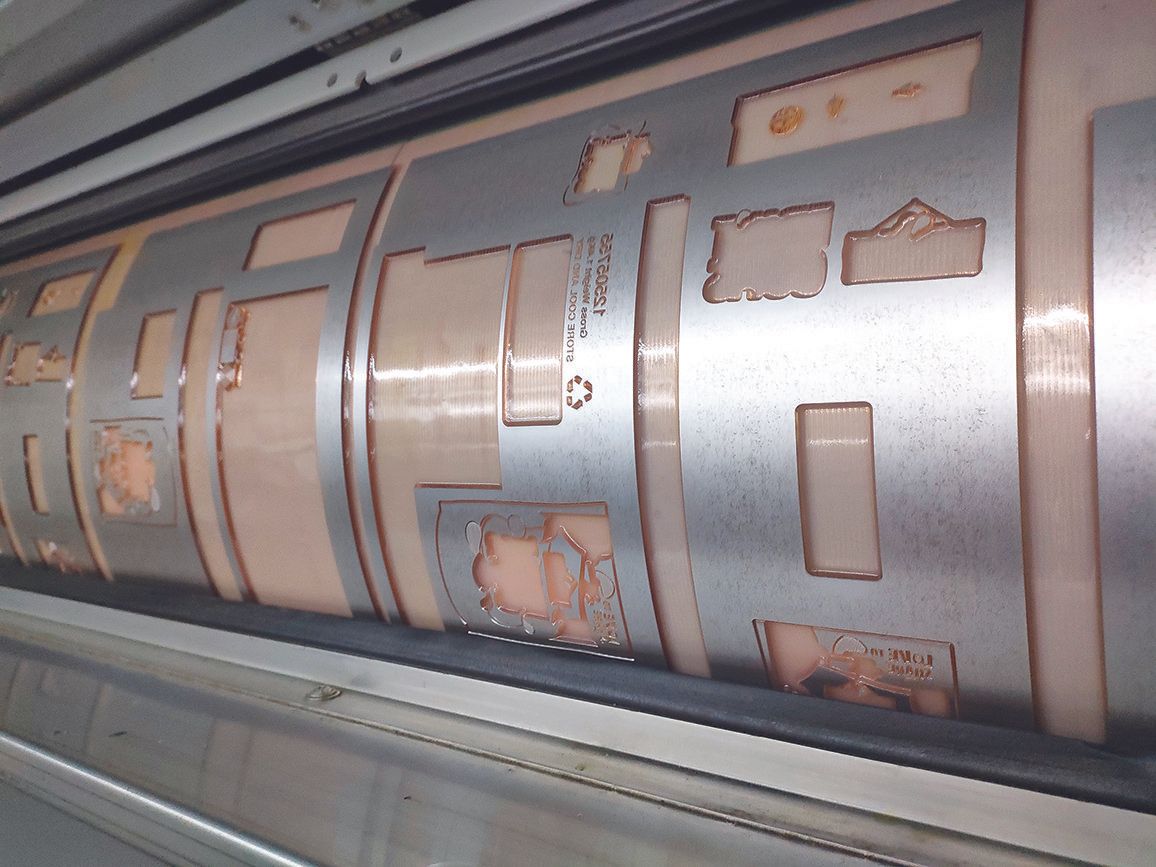

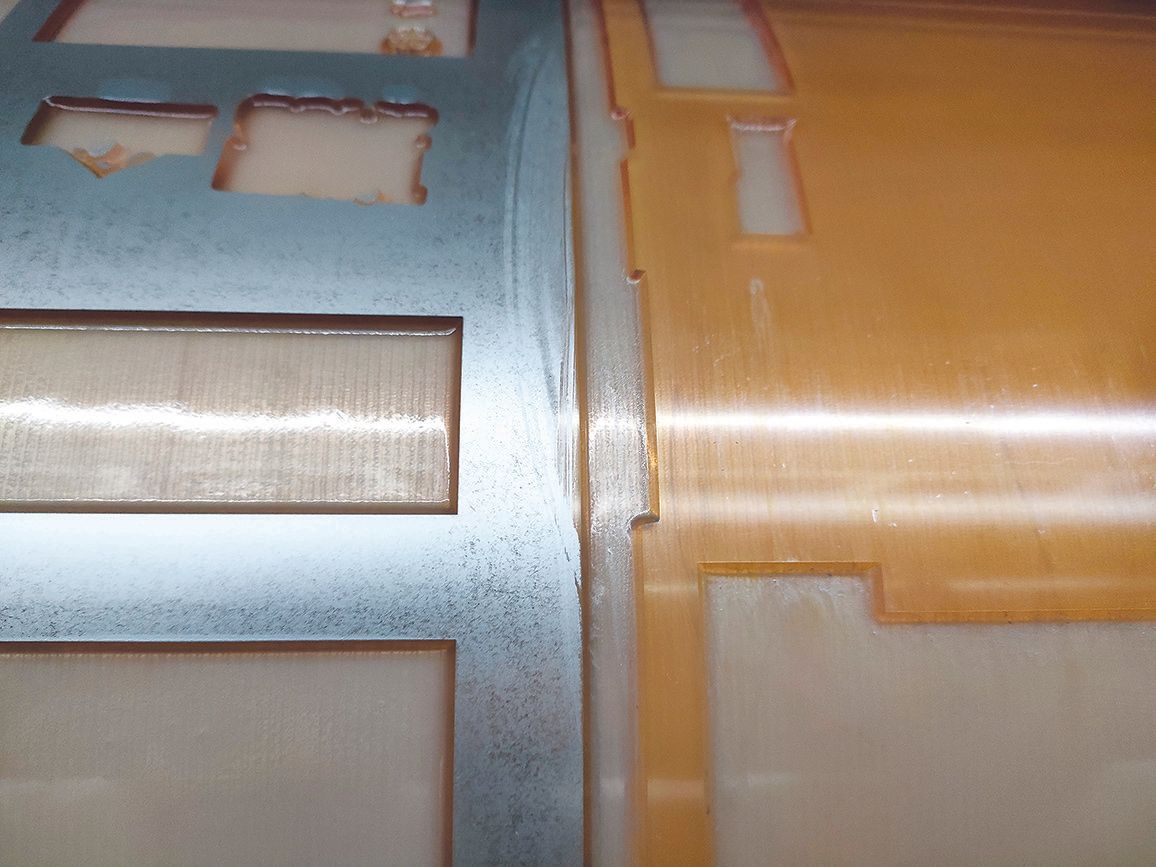

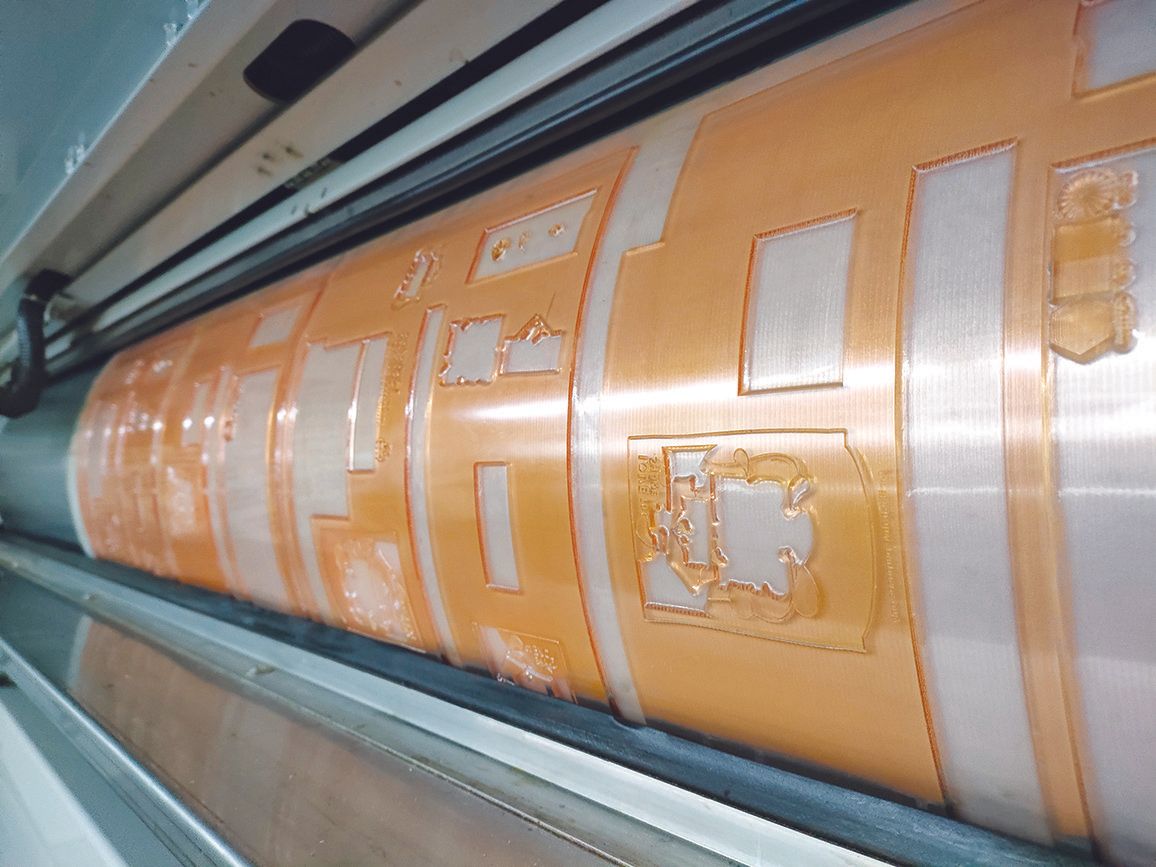

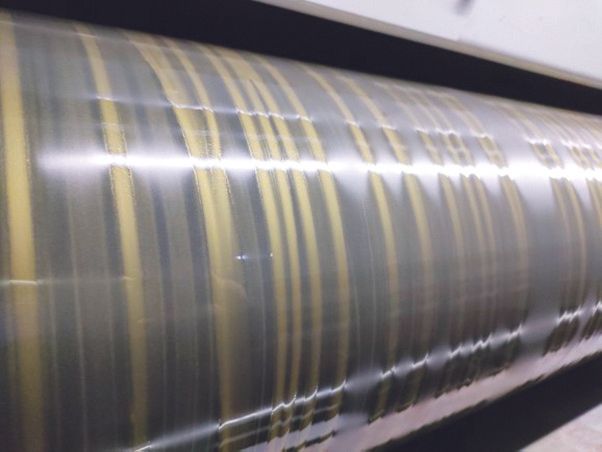

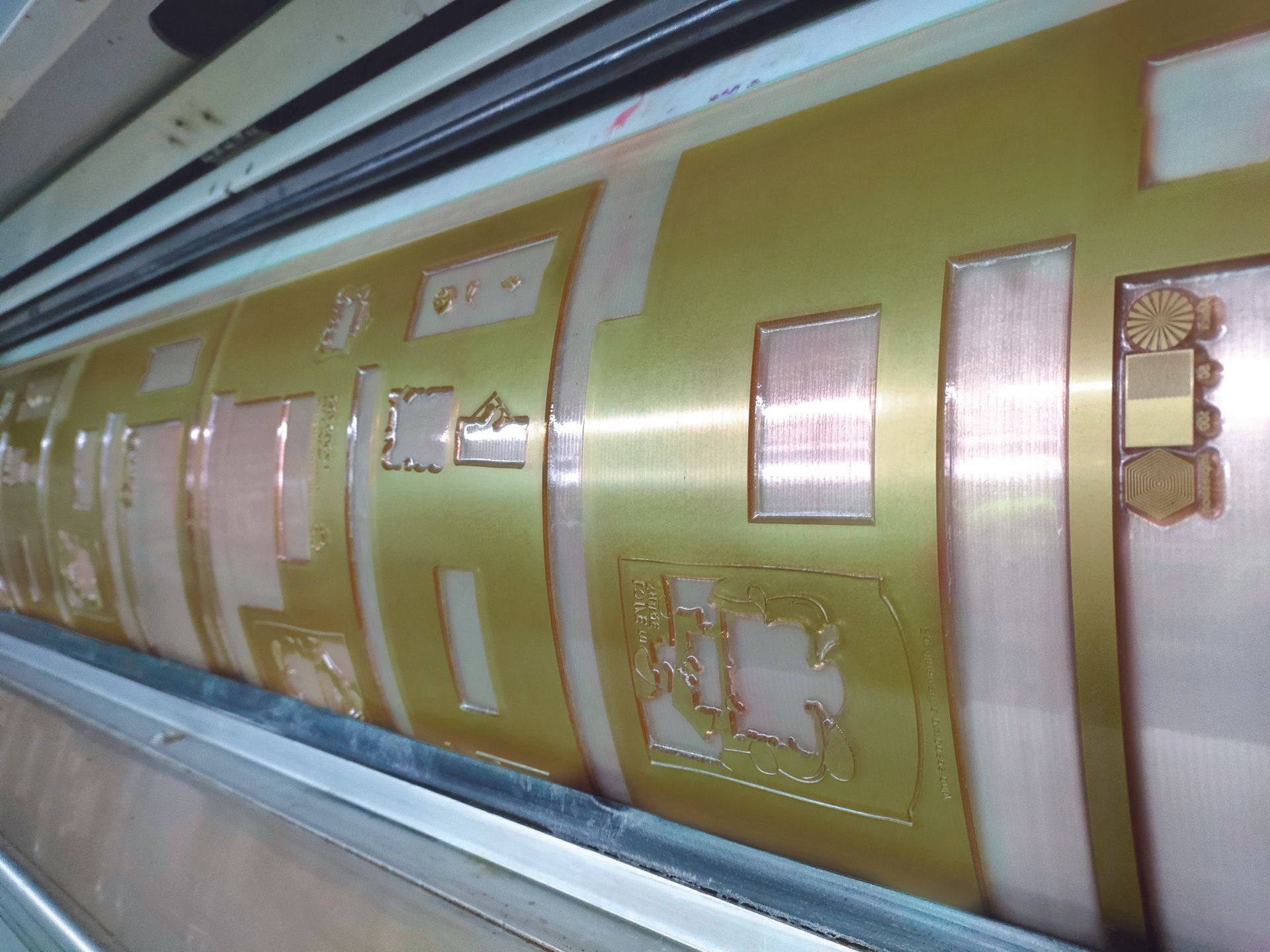

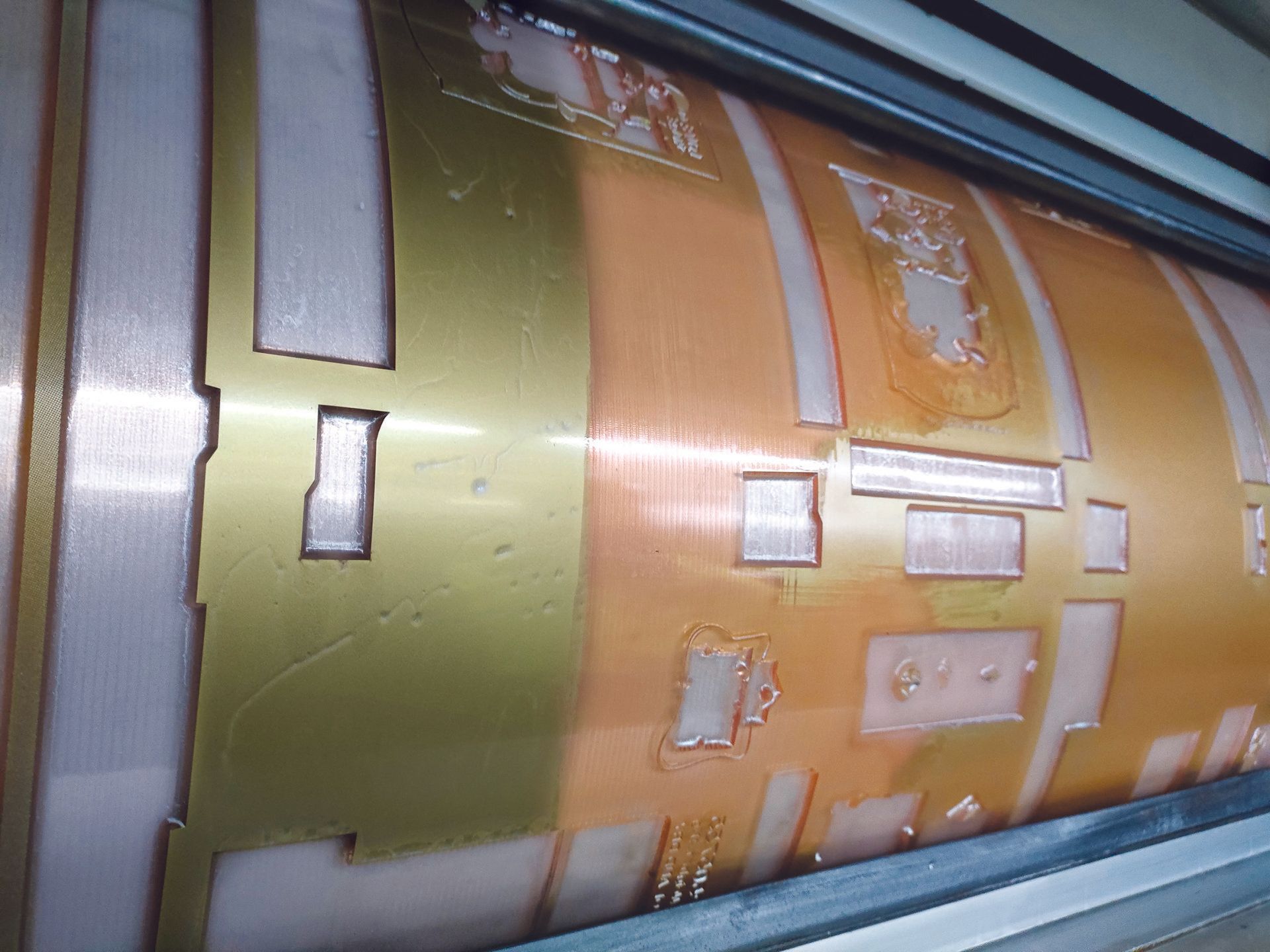

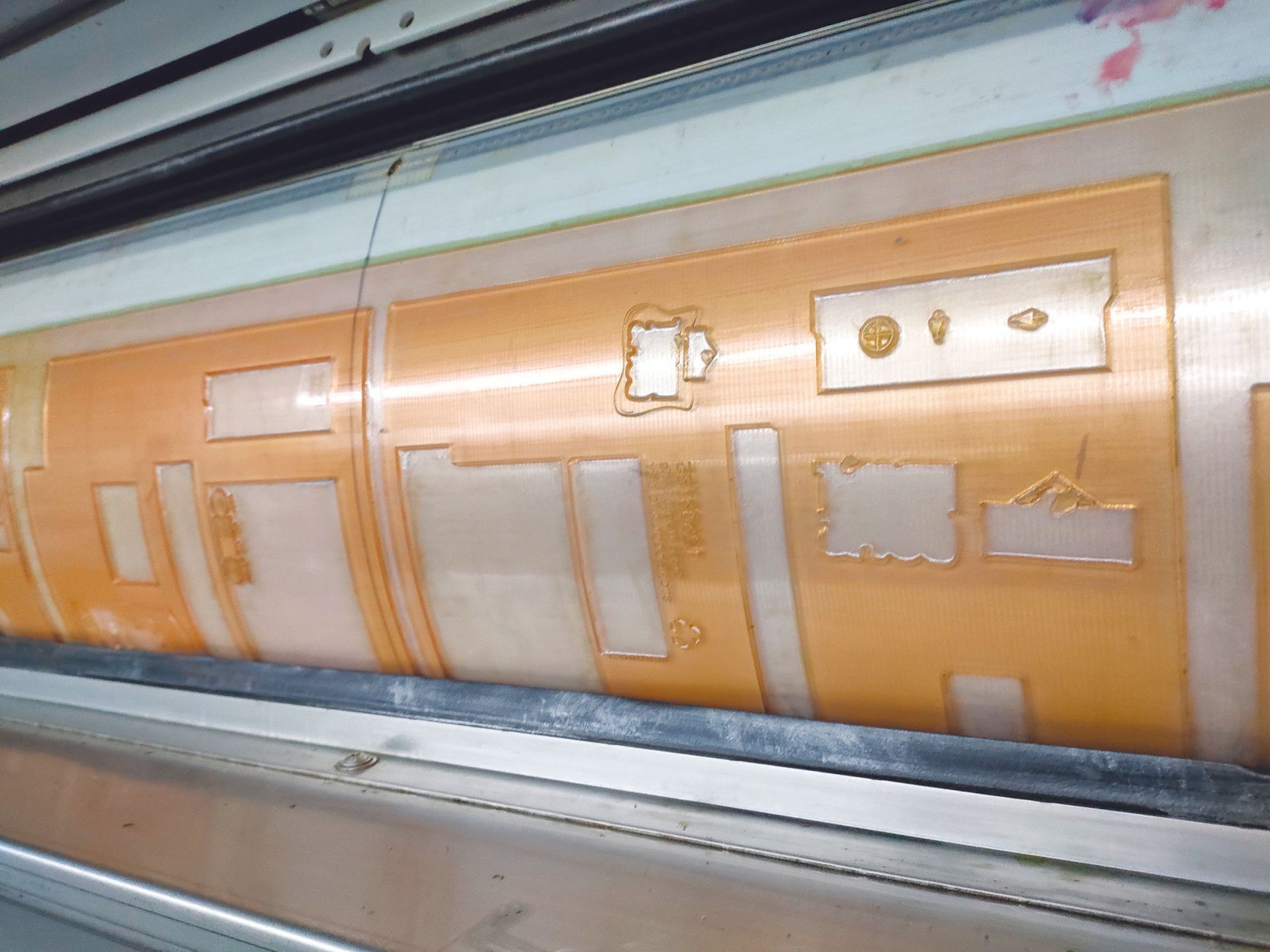

Metallic inks have a different composition to that of standard inks, they contain very small particles of ‘metal flakes’ or ‘leaf’ in the form of copper, bronze, zinc or aluminium. These flakes are suspended within the ink, creating the bright, shiny and lustre appearance associated with metallic inks once printed and dried.

Metallic inks deliver simple but effective results when printed correctly, however, they can be difficult to manage on press and generate a host of print cleaning issues. Viscosity guidelines may vary depending on the visual printed coverage and density required.

We recommend you try and maintain the viscosity of metallic inks at around 25 - 30 seconds as this will improve the final printed appearance and coverage.

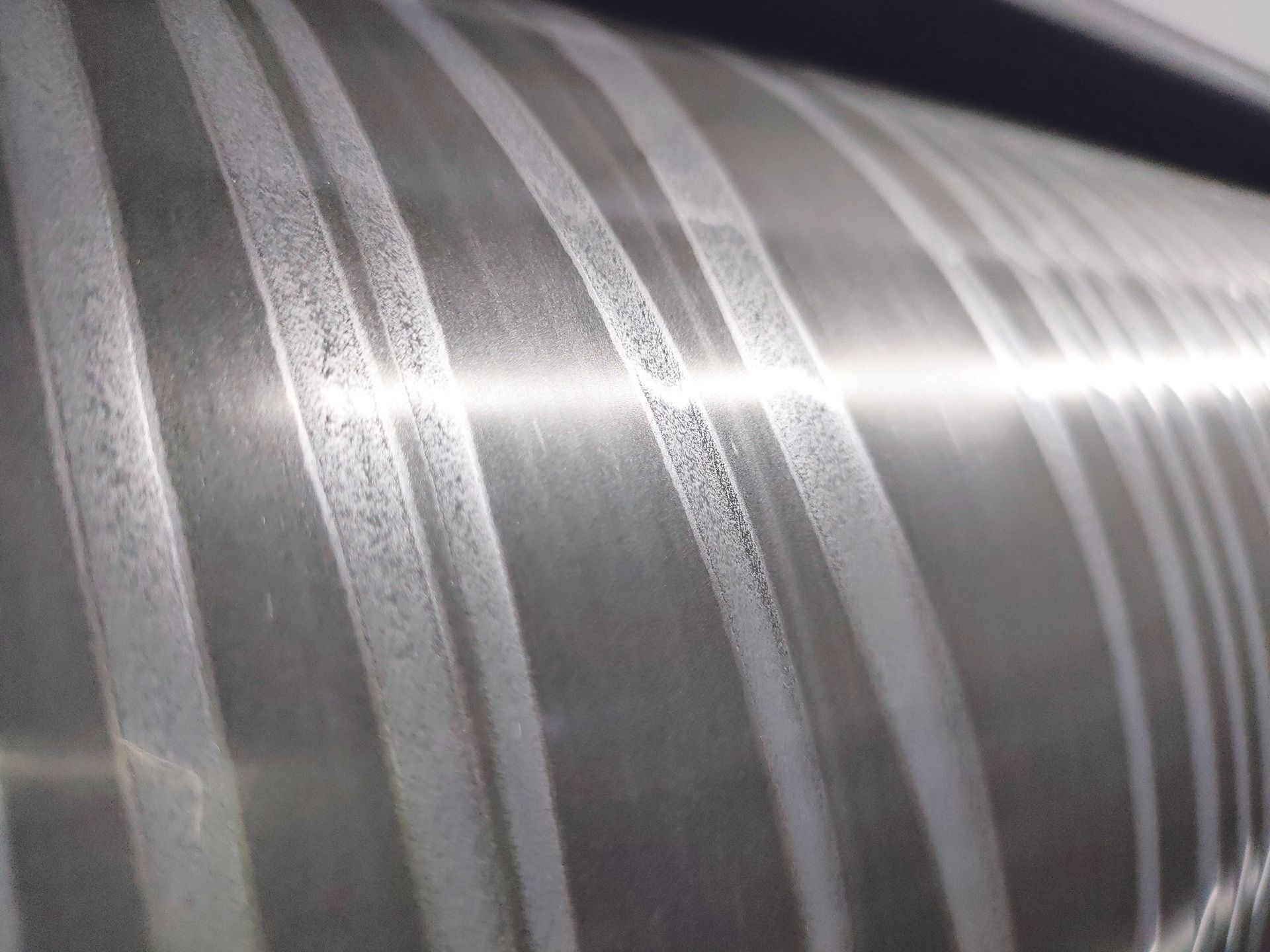

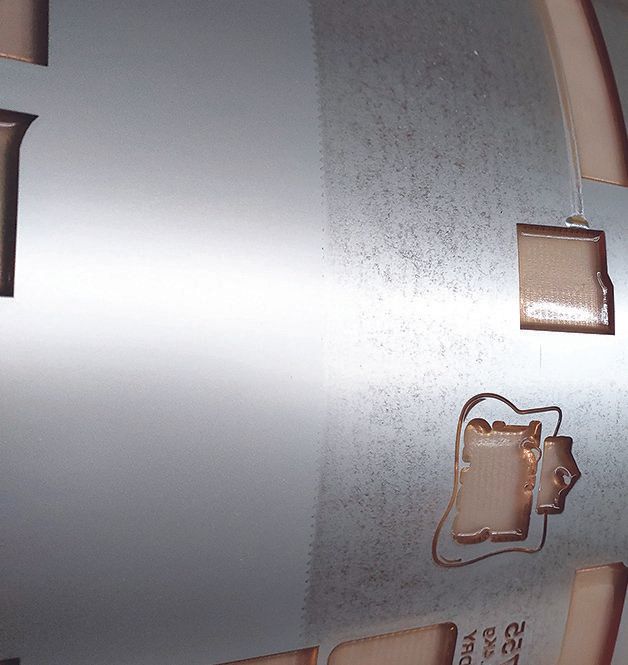

If not cleaned methodically and effectively, metallic inks can block anilox cells, contaminating the whole inking system. If left to dry solid, any metallic ink will become hard and brittle, resulting in small shards or particles dislodging. If these particles enter the ink chamber they can scratch or score anilox rolls, which are expensive to repair. If polymer printing plates are left to dry without immediately cleaning off the fresh metallic ink then more time and effort will be required to clean them.

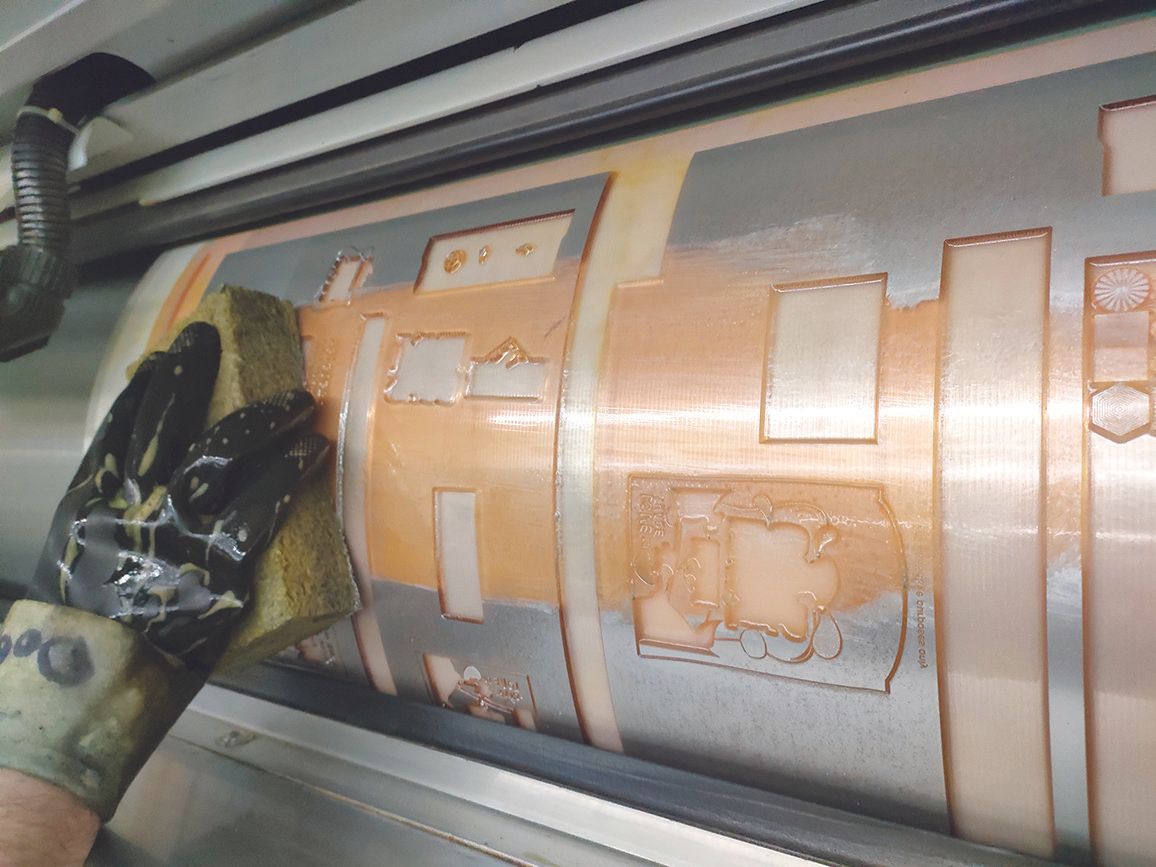

A strict cleaning regime needs to be implemented when printing with metallic inks. This ensures the internal inking system is kept clean but also reduces potential damage and downtime. We recommend a slightly longer auto-dose wash followed by a bucket wash if your machines have a built-in washing system, or an extra-long bucket wash if this your preferred cleaning method.

Contact us for further information and cleaning suggestions for metallic inks.